Overview of “Manufacturing Processes for Engineering Materials 6th Edition”

This comprehensive textbook provides detailed insights into modern manufacturing processes, covering metals, alloys, and advanced technologies. Updated for clarity, it serves engineering students and professionals, emphasizing technical and economic interactions.

The 6th edition of Manufacturing Processes for Engineering Materials introduces updated content, enhanced readability, and improved clarity. It covers advances in manufacturing technologies, emphasizing both traditional and modern methods. The book integrates technical disciplines with economic considerations, providing a balanced approach for understanding manufacturing operations. Designed for engineering students and professionals, it serves as a comprehensive guide to assess the capabilities and limitations of various manufacturing processes. This edition also includes global adaptations, such as SI units, to cater to international standards and accessibility.

Key Features and Updates in the 6th Edition

The 6th edition offers a comprehensive guide to manufacturing processes, featuring updated content and enhanced readability. It includes SI units for global accessibility and digital resources for online learning. New chapters focus on sustainability and modern techniques, aligning with industry trends. Improved clarity and organization ensure a balanced approach, blending technical details with economic considerations. This edition also incorporates feedback from previous versions, making it more student-friendly and relevant for contemporary engineering education.

Authors and Their Contributions

Serope Kalpakjian and Steven R. Schmid are renowned experts in manufacturing and materials engineering. Their contributions to the 6th edition provide updated insights and enhance the textbook’s clarity.

Serope Kalpakjian: Background and Expertise

Serope Kalpakjian is a professor emeritus of mechanical and materials engineering at the Illinois Institute of Technology. He is a leading authority in manufacturing processes and materials science, with extensive contributions to education and research. His expertise spans mechanical processing of materials, lubrication, and metalworking operations. Kalpakjian has authored several influential textbooks, including Manufacturing Processes for Engineering Materials and Manufacturing Engineering, which are widely used in academic and professional settings. His work emphasizes the integration of technical and economic aspects of manufacturing.

Steven R. Schmid: Role in the 6th Edition

Steven R. Schmid significantly contributed to the 6th edition, enhancing its clarity and relevance. As a co-author, he brought expertise in mechanical engineering and manufacturing processes, ensuring the text reflects current industry trends. Schmid’s involvement emphasized the integration of technical disciplines and economic considerations, making the book a valuable resource for both students and professionals. His updates and revisions align with modern manufacturing practices, providing a comprehensive understanding of materials and processes.

Core Topics Covered in the Book

The text covers manufacturing processes for metals, alloys, and advanced materials, including metal casting, machining, and non-traditional methods like 3D printing and laser processing.

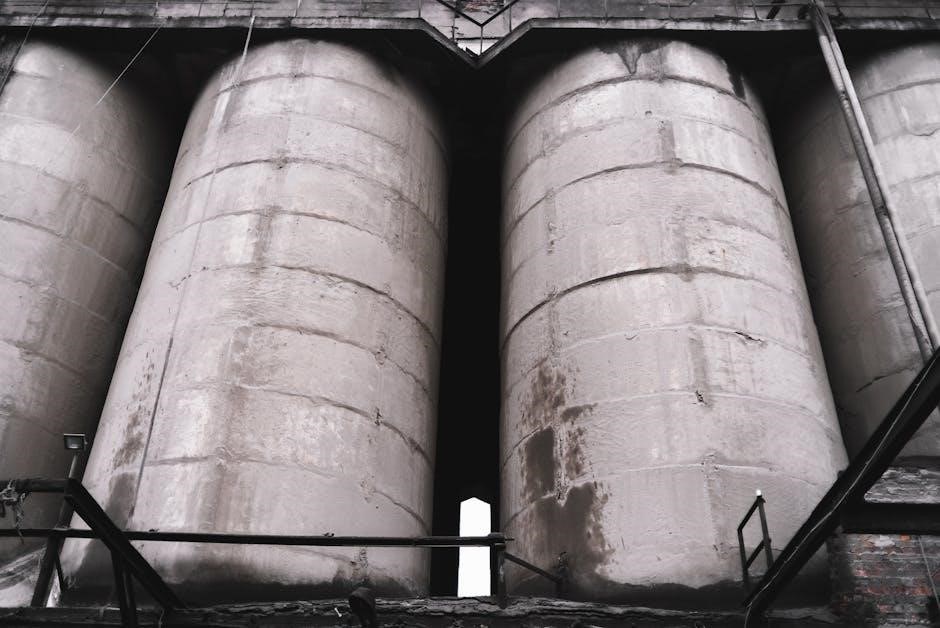

Manufacturing Processes for Metals and Alloys

The book extensively covers traditional and modern manufacturing processes for metals and alloys, including casting, forging, and machining. It also explores heat treatment, surface finishing, and non-traditional methods like 3D printing. Emphasis is placed on understanding material properties, process capabilities, and economic considerations. Practical applications in industrial settings are highlighted, providing students with a comprehensive understanding of how metals and alloys are shaped and processed. This section bridges theory and practice, making it invaluable for engineering education and professional reference.

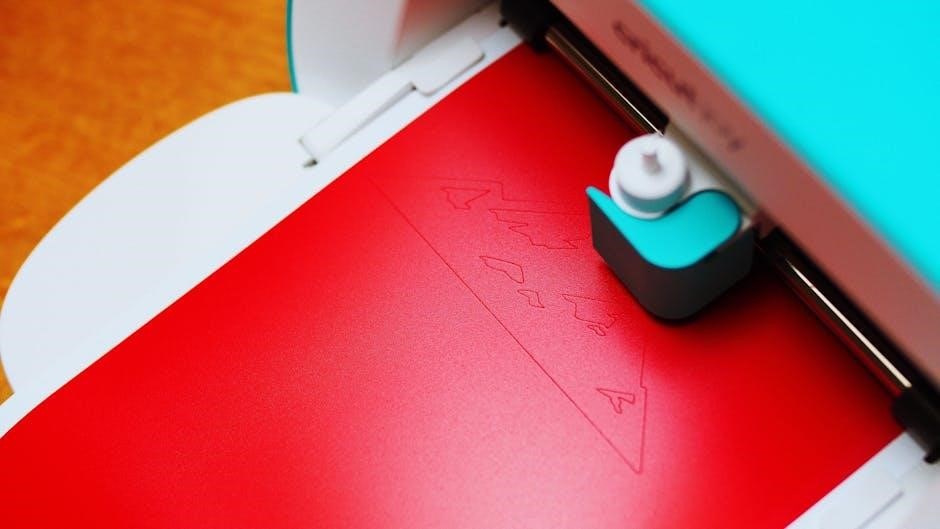

Advanced Manufacturing Technologies

The 6th edition delves into cutting-edge manufacturing technologies, such as additive manufacturing, automation, and robotics. It explores advancements in 3D printing, laser processing, and smart manufacturing systems. These technologies are integrated with traditional methods to enhance efficiency and precision. The book highlights how these innovations reduce material waste, improve product quality, and enable sustainable production. By addressing the latest industry trends, it prepares students and professionals to embrace modern manufacturing challenges and opportunities, ensuring they are well-versed in both conventional and emerging techniques.

Importance of the Book in Engineering Education

This textbook is crucial for engineering education, bridging theory and practice by integrating technical disciplines with economic considerations. It prepares students for real-world manufacturing challenges.

Integration of Technical Disciplines and Economics

The 6th Edition excels by merging technical disciplines with economic analysis, providing students a holistic understanding of manufacturing. It emphasizes cost-effectiveness, efficiency, and sustainability, preparing them for real-world decision-making in engineering and production environments.

Publishing Details and Editions

ISBN-10: 0134290550, ISBN-13: 978-0134290553, published by Pearson on August 17, 2016. This 1,136-page hardcover is a key resource for engineering education and practice.

ISBN and Publication Information

The 6th edition of “Manufacturing Processes for Engineering Materials” holds ISBN-10: 0134290550 and ISBN-13: 978-0134290553. Published by Pearson on August 17, 2016, this 1,136-page hardcover is a key resource for engineering education and practice, offering comprehensive coverage of manufacturing processes and materials.

Global Edition and SI Units Adaptation

The 6th edition is available in a global version, adaptated for international use with SI units. This ensures accessibility and relevance worldwide, catering to diverse engineering education systems and professional practices.

Learning Resources and Supplements

The 6th edition offers a solution manual and digital access, providing students with additional study tools, flashcards, and audio resources to enhance their learning experience effectively.

Solution Manual for the 6th Edition

The solution manual for the 6th edition provides detailed answers and explanations for textbook problems, helping students understand complex concepts. It covers all chapters and is available for download as a PDF. This resource is particularly useful for self-study and exam preparation, offering clear solutions to exercises and case studies. Instructors can also use it to create homework assignments and quizzes, ensuring a comprehensive understanding of manufacturing processes.

Digital Access and Online Resources

Digital access to the 6th edition is available through various platforms, offering flexibility for students and professionals. The book can be downloaded as a PDF, and online resources include flashcards, audio summaries, and interactive study aids. Pearson provides a 14-day refund guarantee for digital purchases, ensuring satisfaction. Additionally, rental options and mobile access allow learners to study anytime, anywhere. These resources enhance understanding and convenience, making the 6th edition a valuable tool for engineering education and professional development.

Recent Advances in Manufacturing Processes

The 6th edition highlights cutting-edge advancements in manufacturing, including sustainable practices, additive manufacturing, and smart technologies. These updates reflect current industry trends and innovations, ensuring relevance.

Updates in the 6th Edition Reflecting Industry Trends

The 6th edition incorporates the latest advancements in manufacturing, such as sustainable practices, additive manufacturing, and smart technologies. These updates align with current industry trends, ensuring the content remains relevant and forward-looking. The book emphasizes the integration of technical and economic considerations, providing a holistic understanding of modern manufacturing processes; This edition also addresses environmental concerns and efficiency improvements, reflecting the evolving priorities of the manufacturing sector. Students and professionals gain insights into cutting-edge techniques and their practical applications, making the text a valuable resource for both academic and industrial settings.

Emphasis on Sustainability and Modern Techniques

The 6th edition places a strong focus on sustainable manufacturing practices and cutting-edge technologies. It explores eco-friendly materials and energy-efficient processes, aligning with global environmental goals. Modern techniques like additive manufacturing and automation are thoroughly covered, highlighting their role in advancing the industry. The text emphasizes minimizing waste and reducing environmental impact while maintaining productivity. This emphasis ensures that students and professionals are well-prepared to address contemporary challenges in manufacturing, fostering innovation and responsible practices in the field.

Availability and Access

The 6th edition is available as a PDF download and through online platforms like Reddit. It can also be rented or purchased via Pearson, ensuring accessibility for engineers and students.

PDF Downloads and Online Platforms

The 6th edition of “Manufacturing Processes for Engineering Materials” is widely available as a PDF download through various online platforms, including Reddit and academic forums. Users can access the complete textbook in digital format, making it convenient for students and professionals to study and reference. Additionally, Pearson offers digital access to the book, along with supplementary resources like solution manuals. The global edition, adapted with SI units, ensures accessibility for an international audience. This availability underscores the book’s relevance in modern engineering education and practice.

Purchase Options and Rental Availability

The 6th edition of “Manufacturing Processes for Engineering Materials” can be purchased in hardcover or rented through platforms like Chegg and Amazon. Pearson offers the book with a 21-day guarantee, while digital access is available for convenience. The global edition, adapted for international markets, is also accessible. ISBN details ensure easy identification for purchase. Rental options provide affordability for students, making the textbook accessible to a broad audience.

Target Audience and Application

Primarily designed for mechanical, industrial, and materials engineering students, this textbook is also valuable for professionals seeking to deepen their understanding of manufacturing processes and technologies.

Use in Academic and Professional Settings

This textbook is widely used in academic programs for mechanical, industrial, and materials engineering students, serving as a core resource for understanding manufacturing principles. Professionals also benefit from its detailed insights into modern manufacturing technologies and practices. The book’s clear presentation and comprehensive coverage make it an essential reference for both educational and industrial applications, helping users stay updated on the latest advancements in the field. Its emphasis on practical applications and real-world challenges enhances its utility in diverse settings.

Relevance for Engineering Professionals

This textbook is a valuable resource for engineering professionals seeking to deepen their understanding of manufacturing processes. It provides insights into cutting-edge technologies and methodologies, ensuring professionals stay updated on industry advancements. The book’s focus on practical applications, economic considerations, and sustainability makes it a reliable reference for those involved in materials processing and production. Its comprehensive coverage of metals, alloys, and advanced manufacturing techniques ensures professionals can apply the knowledge directly to real-world challenges, enhancing their problem-solving and decision-making skills.